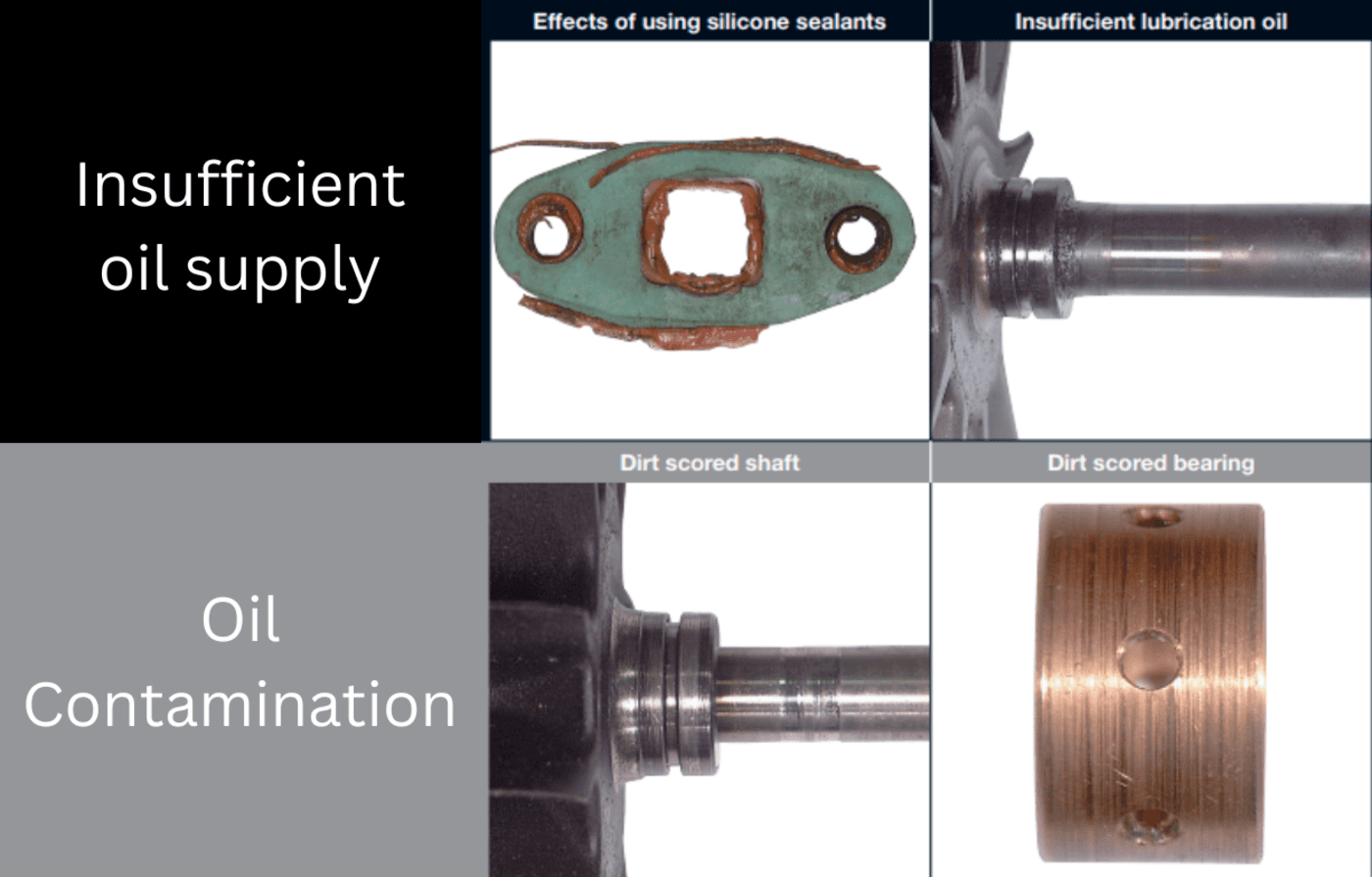

Did you know over 90% of turbo failures are caused by either lack of oil or oil contamination!

As technology changes and turbos become more and more complex, oil supply becomes more critical than ever. Turbos can spin at speeds of over 300,000 revs per minute and reach temperatures close to 1000°C, so a clean and uninterrupted supply of the correct grade oil is essential for the life

of any turbocharger.

If oil is not present at start-up and while the turbo is running, the bearings will fail. Running a turbo without oil for five seconds is as harmful as running an engine without oil for five minutes. We strongly recommend you replace oil pipes to eliminate any carbon deposits or sludge that could enter the turbo or restrict oil flow to the bearings.

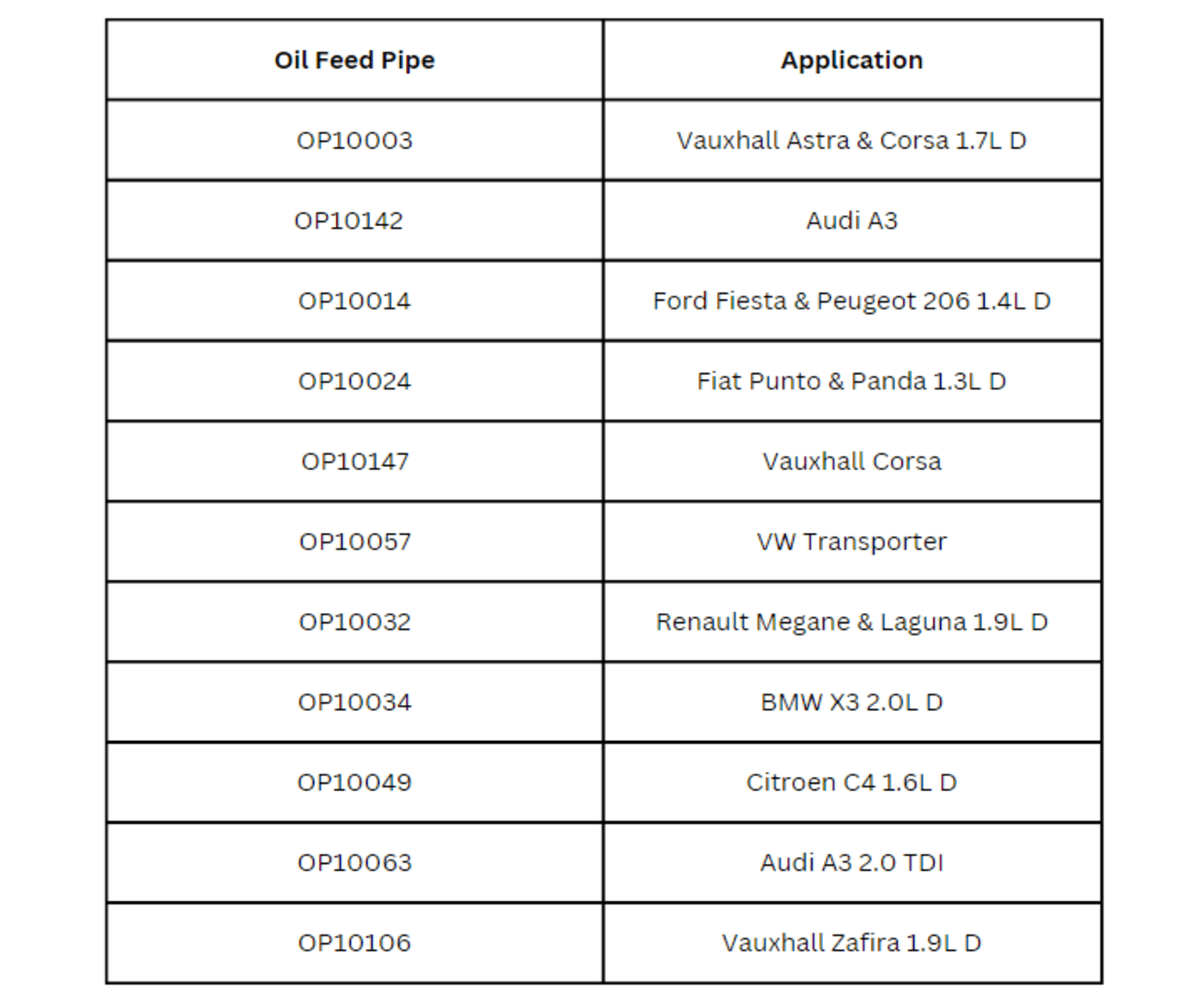

We stock over 250 oil feed pipes for popular applications. We recommend installing new pipes when replacing the turbo to reduce the chances of the replacement turbo failing.